Copyright ©2006 - 2021 HangZhou Longwin Industry Limited

CHINA MOST PROFESSIONAL BATTERY PRODUCT MANUFACTURER

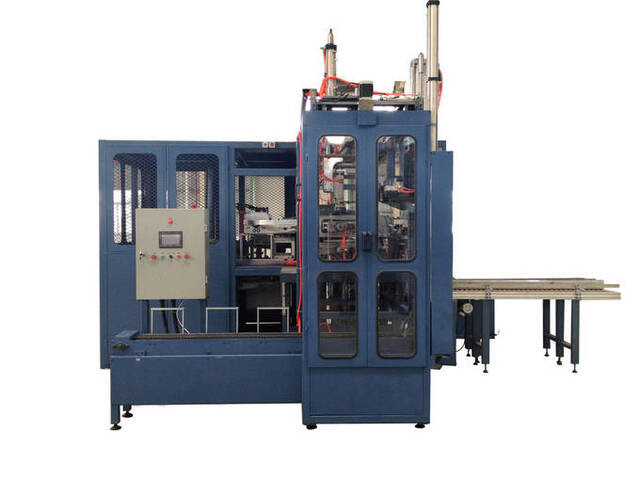

ZHDM40 large-density casting welding machine is our latest large-density casting welding machine, which is suitable for the casting and welding of large-density battery bus bars, bridge welding heads and poles.

| Brand Name | Longwin |

| Product Name | Wonderful ZHDM40 COS machine for traction battery |

| Place of Origin | Zhejiang, China |

| Production efficiency | 80-120 pcs/hour |

| voltage | 380V/50HZ |

| Air consumption | 3m3/hour |

| Certificate: | RoHS |

| power | 42KW |

| Air source | 0.6-0.8MPa Air consumption: 2.4m3L/hour Cooling water: 0.5MPa |

| Dimensions | 3000×2500×2100(L×W×H)mm |

Operator: 2 people;

The main machine adopts a pneumatic intermittent rotary lifting and turntable mechanism, which drives four sets of pneumatic fixtures to rotate to complete the clamping and forwarding function of the four-station pole group;

The main machine turntable is lifted and lowered once every time it rotates 90º, and it rotates in turn through the pneumatic intermittent rotary lifting turntable mechanism; four processes of installation of pole groups, arrangement of ear brushes, mold casting and welding, and removal of pole groups;

The first station is the installation process of the pole group: it is composed of a cylinder lifting plate mechanism and a pneumatic clamp. During operation, the cylinder lifting pallet mechanism cooperates with the pneumatic fixture on the turntable to manually operate the pole group to complete the loading, clamping, and fixture turning 180°. At this point, the filling process of the pole group is completed, preparing for the next process;

The second station is the process of brushing ear immersion agent: it is composed of a cylinder lifting support plate mechanism, a pneumatic fixture, a reciprocating platform (brushes, wire brushes and flux boxes), and a finishing mechanism. Its function is to arrange the pole ears of the pole group first, then use a wire brush to remove the oxide layer on the pole ears, and then brush the pole ears with a brush dipped in flux so that the flux is evenly brushed on the pole ears. This process is Autocomplete

The third station is the casting and welding process: it is composed of a cylinder lifting mechanism and a pneumatic fixture, a mold, a demolding mechanism, a lead melting furnace, a lead pump, and a cooling system. The working condition of this station directly affects the quality of the cast welding pole group. This process is done automatically;

The fourth station is the pole group removal and installation slot. It is composed of a cylinder lifting pallet mechanism and a pneumatic clamp. Flip the fixture that was turned 180° before this to its original state, then loosen the fixture to drop the cast and welded pole group on the pneumatic lifting pallet, and manually take out the pole group and install the groove to complete the entire welding process.

battery assembly

Fax:+86-571-87797895

CHINA MOST PROFESSIONAL BATTERY PRODUCT MANUFACTURER